Craftsmanship Redefined Best AC Contactors from China Serving Global Industries

In recent years, the global demand for AC contactors has witnessed significant growth, driven by the expansion of the industrial sector and the increasing need for efficient electrical control solutions. According to a report by MarketsandMarkets, the AC contactor market is expected to reach USD 5.26 billion by 2026, growing at a CAGR of 5.3%. This trend underscores the pivotal role that AC contactors play in various industries, facilitating the reliable operation of high-power electrical devices. China's manufacturing prowess, exemplified by its commitment to quality and innovation, has positioned it as a leading supplier in this sector. The phrase "中国制造,以品质赢得世界尊重" aptly captures the essence of China's influence in the global market—where manufacturing excellence translates to respect and trust on the world stage, especially in the development and supply of high-quality AC contactors.

Understanding the Key Features of AC Contactors in Modern Industries

In modern industries, AC contactors play a crucial role in controlling the electrical supply to motors and other load circuits. The evolution of these devices has been driven by the need for increased efficiency and reliability, especially as global energy consumption continues to rise. According to a recent report by MarketsandMarkets, the global AC contactor market is projected to reach $4.45 billion by 2026, indicating a compound annual growth rate (CAGR) of 5.2%, underscoring their importance in various applications, from manufacturing to HVAC systems.

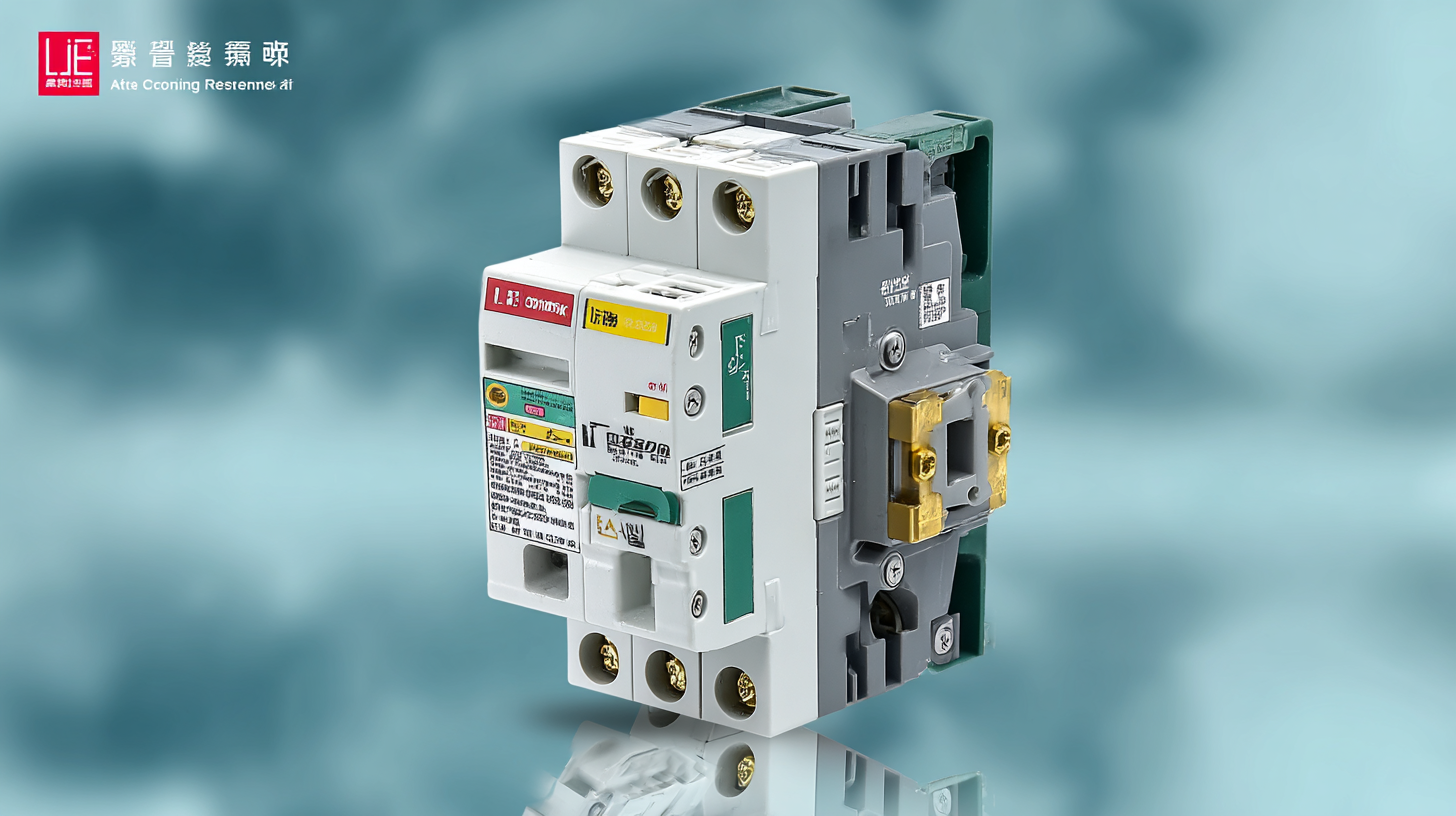

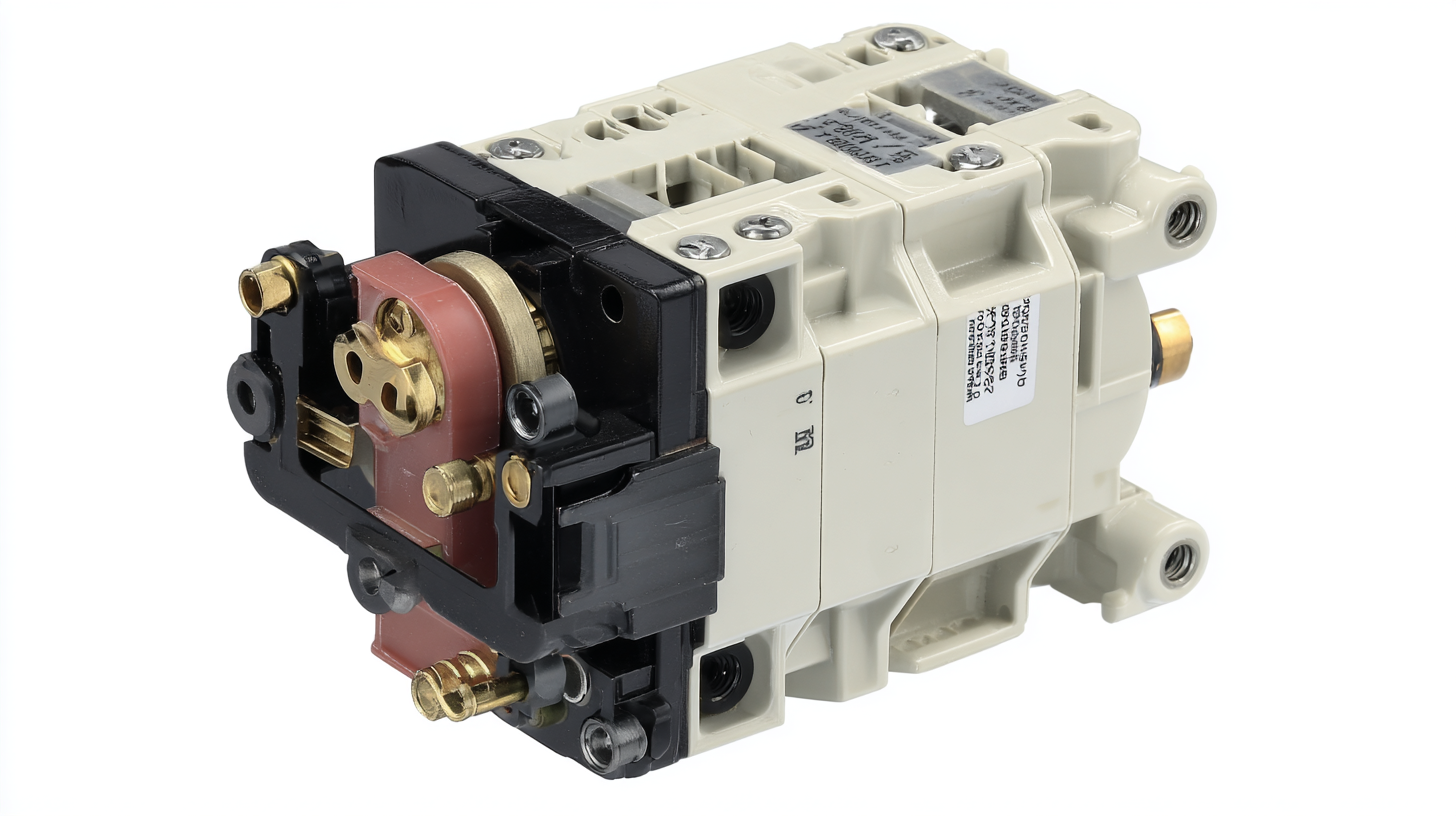

Key features that enhance the performance of AC contactors include thermal and electrical durability, compact size, and innovative materials designed to withstand harsh environments. For instance, high-performance contactors are now often made with environmentally friendly materials, improving safety while maintaining efficiency. In addition, advancements in smart technology have integrated remote monitoring and diagnostics, further elevating operational effectiveness. The robust functionality of these devices not only ensures optimized energy management but also supports sustainable practices across industries, making them indispensable in the modern industrial landscape.

The Different Types of AC Contactors and Their Applications

In the world of industrial applications, AC contactors play a crucial role in managing electrical loads efficiently. There are different types of AC contactors, each suited for specific applications. For instance, the star-delta combination is an effective configuration for high-output applications (above 5.5 kW), significantly reducing the starting current and ensuring a smoother startup process. This setup is particularly valuable in industries requiring heavy machinery that can experience high inrush currents.

Understanding the response of AC contactors under various electrical loads is essential. Recent studies reveal that external factors, such as voltage dips and supply interruptions, can considerably affect the performance of contactors. It is vital to choose a contactor that not only matches the application requirements but can also handle potential power quality disturbances effectively.

**Tips:**

When selecting an AC contactor, prioritize those compatible with a variety of electrical loads to ensure reliability under fluctuating conditions. Additionally, consider contactors that feature built-in protection mechanisms to guard against voltage dips and other disturbances, enhancing system stability in critical operations. Always consult with manufacturers to obtain specific recommendations based on the intended application.

Craftsmanship Redefined: Best AC Contactors from China Serving Global Industries

How to Choose the Right AC Contactor for Your Needs

When selecting the right AC contactor for your needs, it is crucial to consider the different types available and their applications in various industries. For electric vehicles, renewable energy systems, aerospace, and industrial machinery, the choice between definite purpose and general purpose DC contactors can significantly influence performance and reliability. Definite purpose contactors are specifically designed for particular uses, offering optimized efficiency and safety. In contrast, general purpose contactors provide versatile solutions that can accommodate a variety of applications.

As the demand for electric vehicles continues to surge, the market for DC contactors is expected to follow suit, with a projected market value of $113.7 million in 2023 and a robust CAGR of 7.4% from 2024 to 2032. This growth trajectory is driven by technological advancements and increasing requirements in developing countries, where innovative contactor designs are becoming essential. Additionally, the Asia-Pacific region is anticipated to witness a significant expansion in the DC contactor market, fueled by the rising adoption of electric vehicles, which can exceed a market size of $1.92 billion by 2032. Understanding these dynamics will help users make informed choices that align with their operational requirements.

Quality Assurance: What to Look for in Chinese AC Contactors

When selecting AC contactors from China, quality assurance should be a top priority for industries worldwide.

The first aspect to consider is the manufacturing standards. Reputable Chinese manufacturers often comply with international certifications such as ISO, CE, and UL.

These certifications indicate adherence to stringent quality control processes and product safety regulations, ensuring that the contactors are reliable for various industrial applications.

Another crucial factor is the material used in the construction of the contactors. High-quality materials not only enhance durability but also improve performance in demanding environments.

Look for contactors made with superior copper or aluminum contacts, which offer better conductivity and longer operational life. Additionally, inquire about the testing procedures the manufacturer employs to validate their products.

Comprehensive testing, including temperature and mechanical stress tests, can provide assurance that the contactors will function optimally, even under challenging conditions.

Innovative Manufacturing Techniques Driving AC Contactor Development

In the ever-evolving landscape of industrial manufacturing, innovative techniques are redefining the development of AC contactors. The integration of advanced technologies such as automation, 3D printing, and real-time data analytics is revolutionizing how these essential components are produced. Chinese manufacturers are at the forefront, leveraging these innovations to enhance efficiency, reduce costs, and improve product reliability. This shift not only benefits domestic markets but also positions China as a critical player in global supply chains for electrical components.

Tips: Consider exploring partnerships with manufacturers who utilize cutting-edge technologies to ensure you receive the best products available. Additionally, staying informed about advancements in manufacturing practices can help you make strategic decisions that align with industry trends.

Moreover, the AC contactor market is projected to experience significant growth driven by increasing demand in sectors such as renewable energy and electric vehicles. The development of more robust and environmentally friendly manufacturing processes is essential to meet the rising expectations for sustainability. By prioritizing these innovations, manufacturers can not only enhance their product offerings but also contribute to a greener future.

Tips: Regularly evaluate the market landscape to identify emerging trends and technologies that could impact your operations. This proactive approach will ensure your business stays competitive in an increasingly dynamic environment.

Craftsmanship Redefined Best AC Contactors from China Serving Global Industries - Innovative Manufacturing Techniques Driving AC Contactor Development

| Model | Rated Current (A) | Voltage Rating (V) | Pole Configuration | Application | Manufacturing Technique |

|---|---|---|---|---|---|

| AC1234 | 30 | 400 | 3-Pole | HVAC Systems | Advanced Automation |

| AC5678 | 50 | 600 | 4-Pole | Industrial Motors | Robot-Assisted Assembly |

| AC9101 | 25 | 230 | 2-Pole | Home Appliances | Lean Manufacturing |

| AC2345 | 40 | 500 | 3-Pole | Refrigeration Units | Precision Engineering |

| AC6789 | 15 | 480 | 2-Pole | Lighting Control | Eco-Friendly Materials |