Futureproofing with Best Plastic Waterproof Junction Box Innovations and Strategies for 2025 Industry Trends

In an era where sustainability and resilience have become paramount, the role of the Plastic Waterproof Junction Box in electrical systems is gaining unprecedented importance. According to a recent market report by Research and Markets, the global junction box market is projected to grow at a CAGR of 5.2% from 2023 to 2028, driven by the increasing demand for robust and waterproof solutions across various industries, including construction and renewable energy. As we approach 2025, innovations in materials and design for Plastic Waterproof Junction Boxes will not only enhance their performance but also contribute to futureproofing our infrastructure against environmental challenges. As the "world's factory," China continues to lead in manufacturing advancements, setting trends that ripple through the global market. This blog explores the latest innovations and strategies surrounding Plastic Waterproof Junction Boxes that are essential for staying ahead in this rapidly evolving industry landscape.

Innovative Designs in Plastic Waterproof Junction Boxes for Enhanced Durability

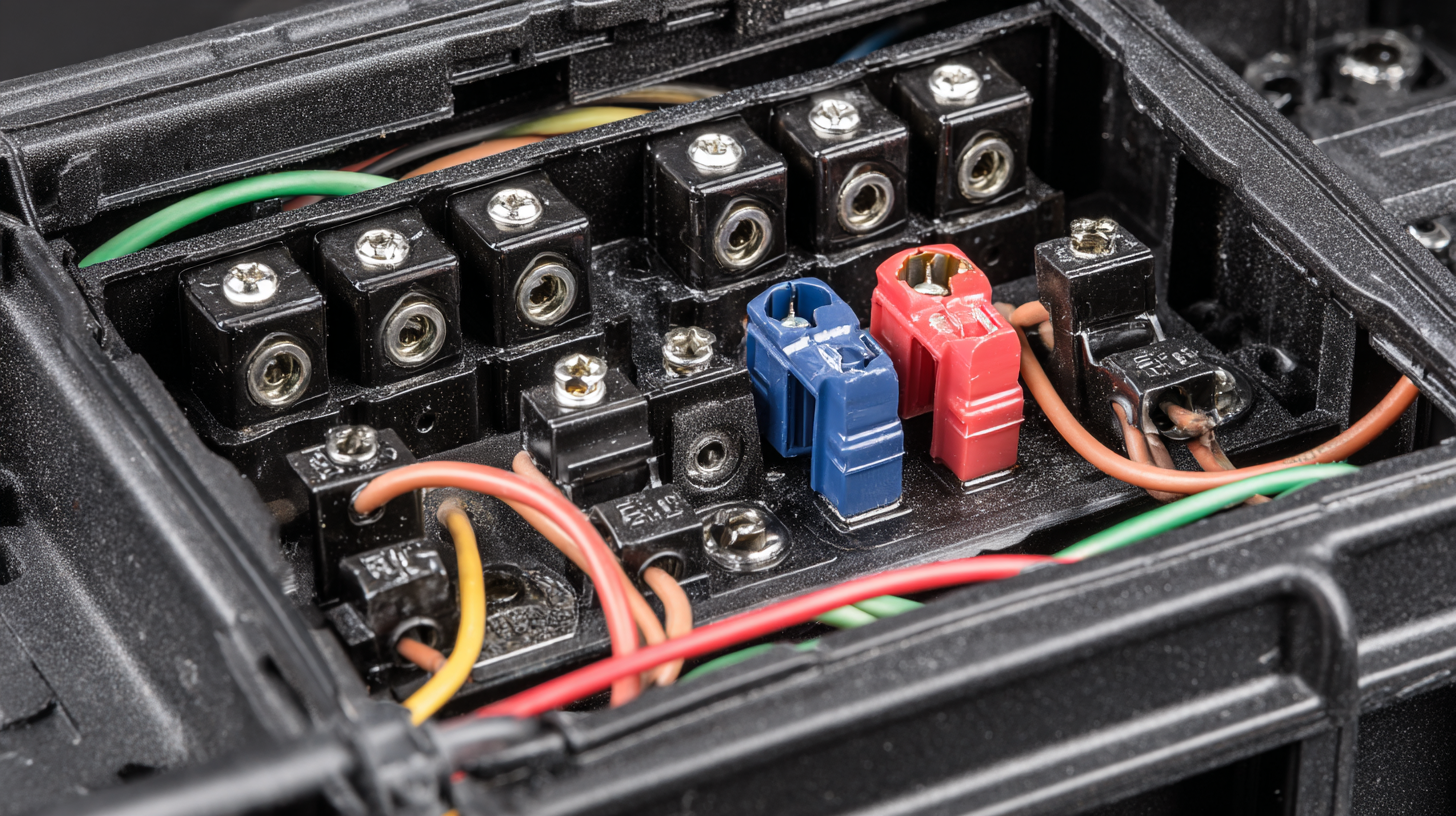

In the ever-evolving landscape of industrial components, plastic waterproof junction boxes have emerged as a vital solution for protecting electrical connections. Innovative designs are taking center stage, focusing on enhanced durability while catering to diverse environmental conditions. One notable trend is the integration of advanced materials that not only provide superior waterproofing but also resist impacts and extreme temperatures. This evolution ensures that junction boxes can withstand the rigors of various applications, from outdoor installations to marine environments.

Additionally, manufacturers are prioritizing user-friendly features in their designs. Modular constructions with quick-connect technologies allow for efficient installations and easy maintenance, saving both time and costs for operators. Enhanced sealing mechanisms and smart venting solutions are also being incorporated to manage pressure and moisture effectively. With these improvements, the next generation of plastic waterproof junction boxes is not just a passive protective unit but an active participant in the efficiency and longevity of electrical systems. As we look towards 2025, the focus on innovative designs promises to redefine standards and expectations within the industry.

Futureproofing Plastic Waterproof Junction Boxes: Market Trends 2025

Key Industry Trends Driving the Adoption of Advanced Waterproof Solutions

As industries continue to evolve, the need for advanced waterproof solutions has become increasingly apparent. Key trends driving the adoption of best plastic waterproof junction box innovations for 2025 revolve around the growing demand for durability and efficiency in various applications. With the rise in outdoor installations and extreme weather conditions, manufacturers are focused on enhancing the resilience of their products. This shift not only prevents equipment failure but also extends the lifespan of electrical systems, making waterproof junction boxes more appealing to businesses looking to futureproof their operations.

Sustainability is another important factor influencing industry trends. Companies are increasingly recognizing the value of eco-friendly materials and manufacturing processes. The development of recyclable and biodegradable plastics, alongside energy-efficient production methods, is paving the way for a more environmentally conscious approach to waterproof solutions. Furthermore, advancements in smart technology integration are enhancing the functionality of these junction boxes, allowing for real-time monitoring and predictive maintenance, which further supports the case for widespread adoption.

As these trends converge, the industry stands poised to embrace innovative strategies that align with both performance and sustainability objectives in the coming years.

Top Features to Look for in Junction Boxes for Futureproofing Needs

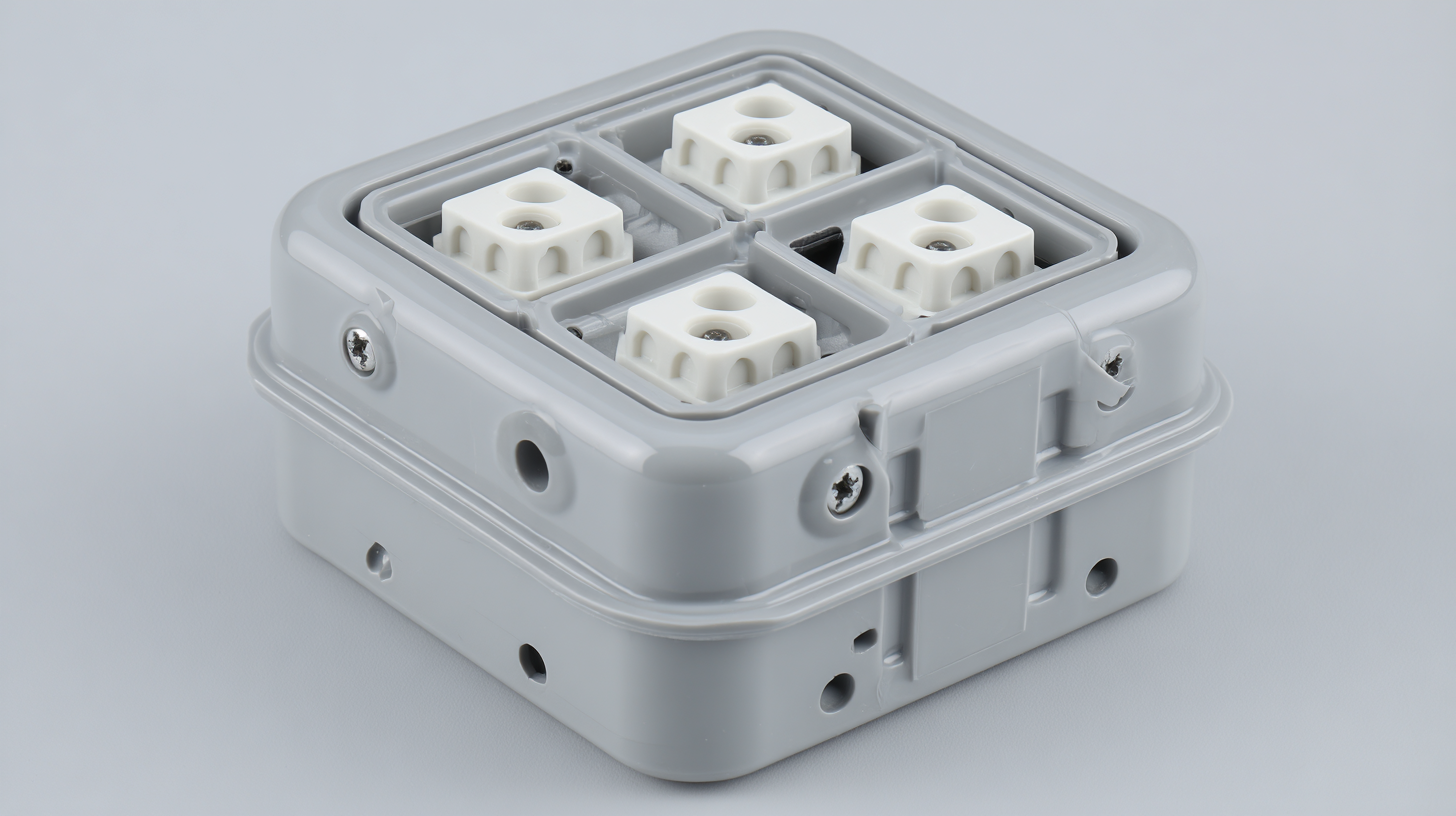

As industries evolve and face challenges from climate change and technological advancements, choosing the right junction boxes becomes increasingly crucial. For futureproofing in 2025, it is essential to look for junction boxes that offer superior waterproofing capabilities, durability, and ease of installation. According to a recent industry report, the waterproof junction box market is projected to grow at a compound annual growth rate (CAGR) of 5.3% through 2025, underscoring the rising demand for reliable protection against harsh environmental conditions.

When selecting a junction box, prioritize features such as robust material construction, rated ingress protection (IP ratings), and compatibility with smart technologies. High-quality plastic materials like polycarbonate and ABS offer strength and resistance to UV light and temperature fluctuations. Moreover, junction boxes with higher IP ratings, such as IP67 or IP68, ensure optimal protection against water and dust intrusion, making them ideal for outdoor applications.

Tips: Consider junction boxes that come with built-in mounting features for easier installation, as this can save time and resources on the job site. Additionally, look for options that allow for tool-free access, facilitating quick adjustments or inspections. Finally, ensure that the chosen junction box complies with relevant industry standards, which can be a significant factor in long-term reliability and safety.

Sustainability Practices in the Development of Plastic Waterproof Junction Boxes

As industries increasingly prioritize environmental sustainability, the development of plastic waterproof junction boxes is undergoing a significant transformation. Innovative manufacturers are implementing eco-friendly practices to ensure their products not only meet operational demands but also align with global sustainability goals. By utilizing recycled materials and focusing on energy-efficient production processes, these companies are minimizing their ecological footprint while enhancing the durability and reliability of junction boxes used in various applications.

According to recent market insights, the global folding cartons market, which reached a valuation of US$ 178.52 billion in 2024, is projected to surge to US$ 288.02 billion by 2033. This substantial growth underscores a broader trend towards sustainable packaging solutions across various sectors. Similarly, the plastic waterproof junction box industry is evolving, with innovations focused on both functional performance and environmental stewardship.

Industry specialists are increasingly advocating for practices such as reduced material waste and the incorporation of biodegradable components, which are essential for futureproofing products against the rising consumer demand for green solutions. As we move towards 2025, these sustainability-focused strategies will become increasingly integral to the success of manufacturers in this crucial sector.

Technological Advancements Shaping the Future of Junction Box Reliability and Performance

As we look towards 2025, the landscape of junction box technology, particularly within solar energy systems, is evolving rapidly. Recent innovations highlight the urgent need for more reliable and efficient junction boxes, especially given the alarming rise in their failure rates in solar applications. Companies are now compelled to rethink their manufacturing processes and employ advanced materials that enhance durability and performance under harsh environmental conditions. This transformation is crucial not only for improving the overall efficiency of solar power systems but also for ensuring the sustainability of photovoltaic modules.

Technological advancements are pivotal in shaping the future of junction boxes, with a focus on high-voltage and high-current solutions tailored for solar installations. The challenges posed by partially repaired modules highlight the importance of robust junction box designs that minimize defects and maximize power output. As the industry moves forward, integrating innovative engineering practices and advanced materials will play a significant role in enhancing the reliability of these critical components. By prioritizing these technological breakthroughs, manufacturers can create junction boxes that not only meet the immediate demands of the solar market but also align with long-term sustainability goals.