5 Industry Standards Defining the Best Plastic Waterproof Junction Box for Quality Assurance

In the world of electrical installations and outdoor applications, the importance of choosing the right components cannot be overstated. One such crucial component is the Plastic Waterproof Junction Box, which plays a pivotal role in safeguarding electrical connections from environmental factors such as moisture and dust. As industries evolve, various standards have emerged to ensure that these junction boxes meet essential quality assurance criteria. In this blog, we will explore five key industry standards that define the best Plastic Waterproof Junction Box for effective performance and durability. By understanding these standards, manufacturers and consumers alike can make informed decisions, ensuring enhanced reliability and safety in their electrical systems. Join us as we delve into the reasons why adhering to these industry benchmarks is vital for maintaining high-quality standards in protective enclosures.

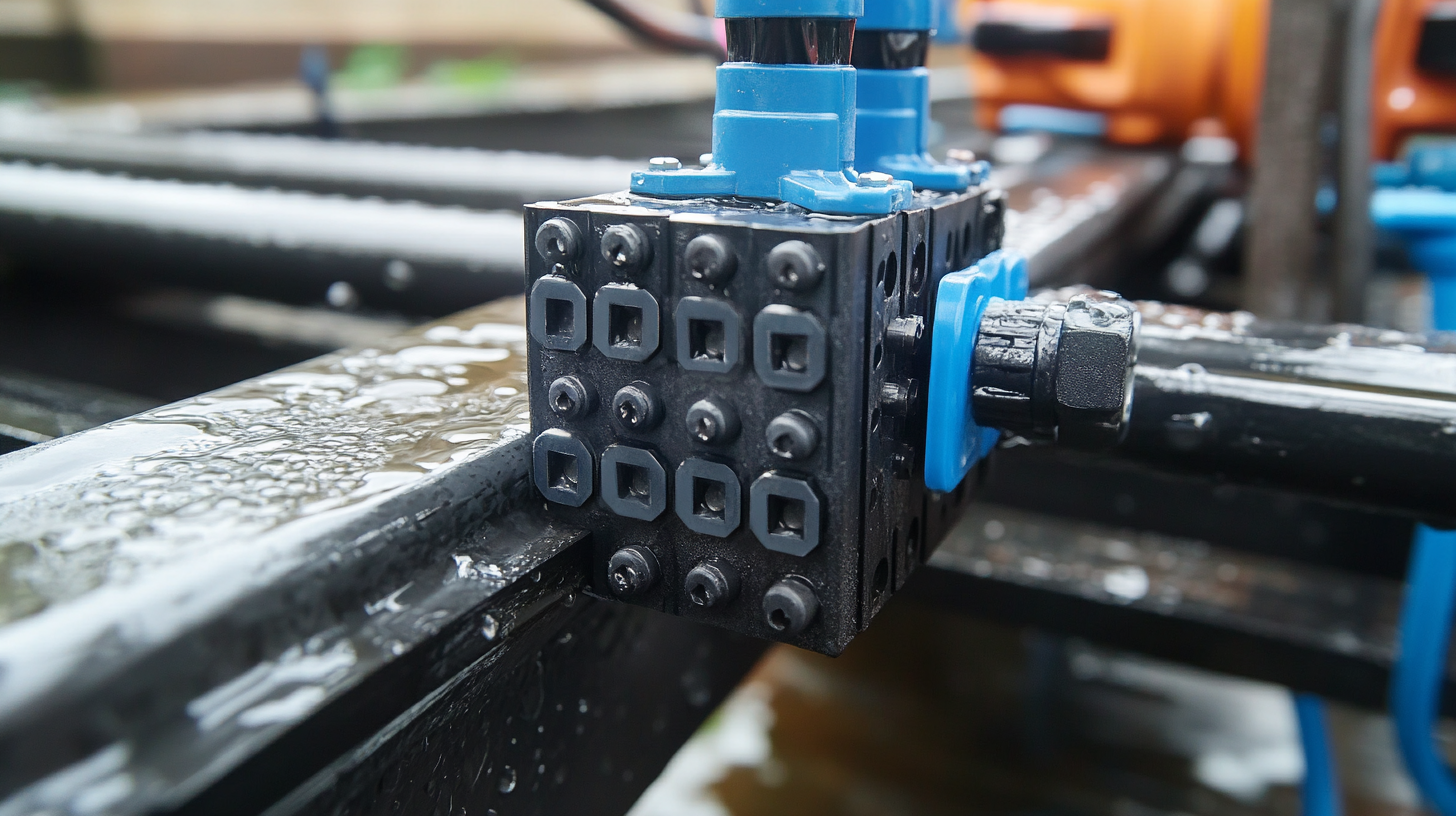

Key Features of High-Quality Plastic Waterproof Junction Boxes in Various Industries

In various industries, the demand for high-quality plastic waterproof junction boxes is driven by the need for durable and reliable electrical connections. Key features that define these products include UV resistance, impact strength, and effective sealing mechanisms to prevent water ingress. According to recent industry reports, the global waterproof sock market is valued at approximately $7.738 million in 2023, with projections indicating growth to $8.06 million by 2024 and a substantial increase to $11.698 million by 2032. This expansion underscores the rising consumer preference for waterproof solutions across applications.

Moreover, industries such as construction, telecommunications, and renewable energy are increasingly relying on these junction boxes to enhance safety and efficiency. High-quality plastic materials not only ensure longevity in harsh environmental conditions but also offer a lightweight alternative to metal, making installation easier. As the market evolves, manufacturers are focusing on innovative designs that meet stringent waterproof standards, reinforcing the importance of quality assurance in product development. Thus, investing in reliable junction boxes is essential for businesses aiming to safeguard their electrical systems and comply with industry regulations.

Common Applications for Plastic Waterproof Junction Boxes in Electrical and Outdoor Settings

Plastic waterproof junction boxes are essential components in both electrical and outdoor settings due to their reliability and protective features. Common applications include outdoor lighting, telecommunications, and irrigation systems. These junction boxes safeguard electrical connections from moisture, dust, and environmental factors, making them ideal for use in harsh conditions. In locations prone to heavy rainfall or humidity, utilizing high-quality waterproof junction boxes is crucial to prevent short circuits and equipment failure.

Tip: When selecting a junction box, ensure it has a minimum Ingress Protection (IP) rating of IP65 or higher. This rating signifies a high level of protection against water and dust, ensuring the longevity of your electrical installations.

Another key application for plastic waterproof junction boxes is in solar power systems. They act as protective enclosures that house electrical components, linking solar panels to inverters and batteries. Using these junction boxes enhances the overall safety and efficiency of solar installations by preventing water-related damage.

Tip: For outdoor installations, choose junction boxes made from UV-resistant materials to ensure they withstand prolonged sunlight exposure without degrading. This choice not only preserves the integrity of the box but also ensures any wiring and connectors inside remain protected over time.

Understanding Different Types of Plastic Waterproof Junction Boxes and Their Benefits

When selecting a plastic waterproof junction box, understanding the different types available is crucial for ensuring quality and functionality. Common types include IP68-rated boxes, which offer the highest level of water and dust protection, making them ideal for outdoor use or in damp environments. These boxes are designed to withstand submersion in water, ensuring that electrical connections remain secure and safe. Typically made of high-quality thermoplastic materials, they resist corrosion and are suitable for various applications, from marine to industrial settings.

Another popular type is the UV-stabilized junction box, designed specifically for prolonged exposure to sunlight. These boxes are perfect for outdoor applications where UV radiation could degrade lesser materials over time. The added benefit of these boxes is their lightweight nature, facilitating easier installation while maintaining durability. Understanding these variations in design and functionality helps engineers and electricians select the most appropriate junction box for their specific needs, providing assurance that their electrical connections are both reliable and protected from the elements.

5 Industry Standards Defining the Best Plastic Waterproof Junction Box for Quality Assurance

| Type | Material | IP Rating | Temperature Range | Applications | Benefits |

|---|---|---|---|---|---|

| Standard Junction Box | Polycarbonate | IP68 | -40 to 100 °C | Outdoor Electrical Installations | Durable, UV resistant, and high impact strength |

| Enclosure Box | ABS Plastic | IP65 | -20 to 80 °C | Indoor and Outdoor Projects | Lightweight, corrosion resistant |

| Weatherproof Junction Box | PVC | IP66 | -30 to 70 °C | Solar Power Systems | Excellent water resistance and lightweight |

| Tamper-Proof Junction Box | Polypropylene | IP67 | -30 to 90 °C | Security Systems | High durability, tamper-resistant design |

| Multi-Function Junction Box | Fiberglass Reinforced Plastic | IP69K | -40 to 121 °C | Industrial Applications | Highest durability and resistant to chemicals |

Industry Standards for Durability and Performance in Junction Boxes

When it comes to selecting a plastic waterproof junction box, understanding industry standards for durability and performance is crucial. These standards serve as benchmarks that ensure the integrity and longevity of junction boxes in various applications. Primarily, the Ingress Protection (IP) rating is essential, as it gauges the degree of protection against dust and water. A higher IP rating indicates a more robust design capable of withstanding harsh environmental conditions, making it vital for outdoor installations.

Additionally, the UL 508A standard focuses on the safety and performance of industrial control panels, including junction boxes. Compliance with this standard means the junction box is tested for electrical safety, which is a key consideration in preventing failures that could lead to costly downtime or safety hazards.

Furthermore, the impact resistance ratings such as IK code illustrate how well a junction box can endure physical impacts, which is particularly important for installations in high-traffic areas or locations prone to mechanical stress. Overall, adhering to these industry standards ensures that manufacturers deliver products that not only meet regulatory requirements but also guarantee long-lasting performance in real-world applications.

Case Studies: Successful Implementations of Plastic Waterproof Junction Boxes in Real-world Scenarios

In recent years, the implementation of plastic waterproof junction boxes has gained traction as industries seek reliable solutions for quality assurance. Case studies highlight how companies have successfully integrated these junction boxes into their systems, showcasing significant improvements in both performance and cost-efficiency. For instance, a study published in the Journal of Applied Materials demonstrated that plastic waterproof junction boxes resulted in a 30% reduction in product failures in various environmental conditions, underscoring their importance in critical applications.

Real-world scenarios reveal the practical advantages of utilizing quality control systems alongside plastic waterproof junction boxes. One case involved a major automotive manufacturer, which incorporated advanced waterproof junction designs into its production process. This shift not only boosted compliance with strict safety standards but also minimized the risks associated with electrical malfunctions. Statistical reports indicate that organizations employing such junction boxes have seen operational costs decline by up to 15%, validating their effectiveness in enhancing durability while maintaining high-quality assurance standards.

As businesses continue to navigate the challenges of quality control, these case studies exemplify the successful application of innovative junction box technologies across various sectors, further reinforcing their status as industry benchmarks.