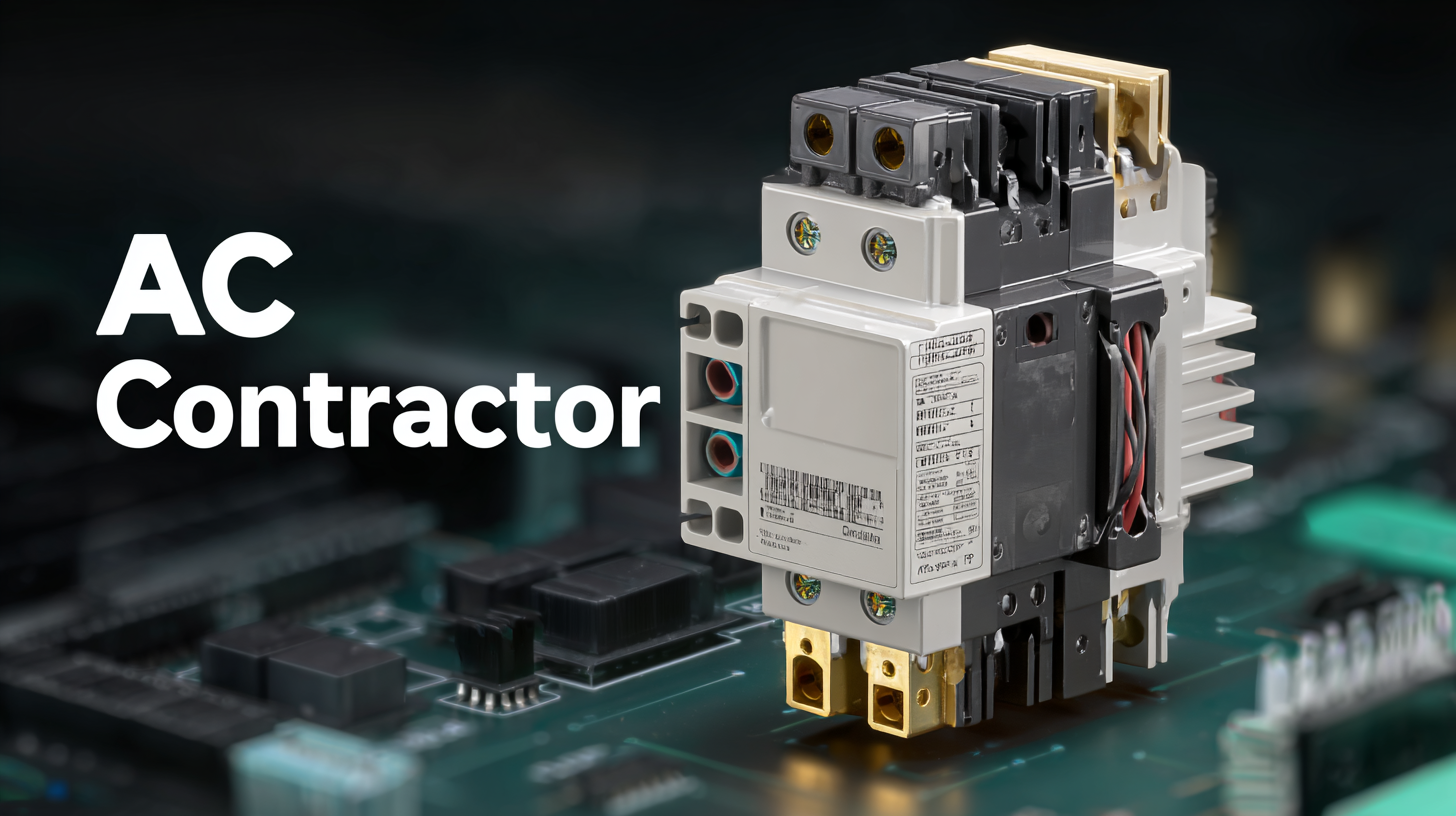

Your Ultimate Guide to Selecting the Best AC Contactor for Global Procurement Success

In the competitive landscape of global procurement, selecting the right components is crucial for ensuring operational efficiency and cost effectiveness. One such component, the AC Contactor, plays a vital role in industrial and commercial applications by facilitating the reliable control of electrical circuits. According to a report by MarketsandMarkets, the global contactor market is expected to grow from USD 5.17 billion in 2020 to USD 6.75 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.5%. As industries increasingly emphasize automation and energy efficiency, understanding the selection criteria for AC Contactors becomes essential. This comprehensive guide provides a checklist to aid procurement professionals in making informed decisions, ensuring that they select AC Contactors that meet both performance and regulatory standards to achieve sustainable success in their operations.

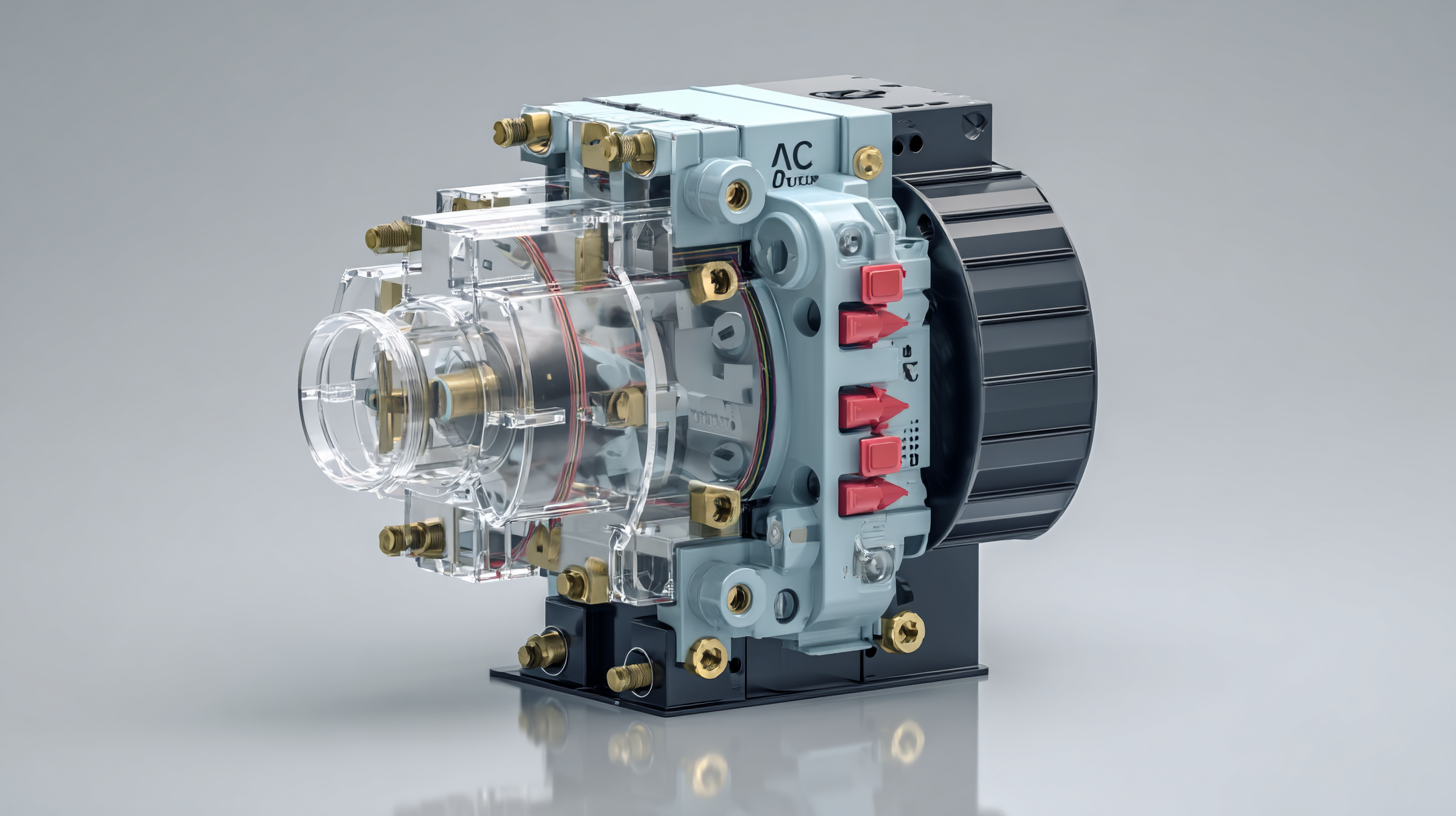

Case Studies of AC Contactor Applications in Different Industries

In the realm of industrial applications, AC contactors play a vital role in managing heavy electrical loads across various sectors. According to a market report by Technavio, the global AC contactor market is expected to grow by $1.3 billion from 2021 to 2025, largely driven by their increased usage in manufacturing and renewable energy sectors. One notable case study comes from the automotive industry, where AC contactors are integral in controlling electric motors and ensuring reliable operation of electric vehicle charging systems. Firms leveraging advanced contactor technology report efficiency gains of up to 20%, reducing operational costs significantly.

Another compelling example can be found in HVAC systems, where AC contactors are critical for compressor control. A report from Frost & Sullivan highlights that the HVAC sector alone represents a substantial portion of the market demand, with an anticipated growth rate of 5.6% annually. Given the push towards energy efficiency and sustainability, companies implementing state-of-the-art AC contactors in their HVAC systems have witnessed energy consumption reductions of as much as 30%. These case studies underscore the importance of selecting the right contactor to enhance operational effectiveness and drive long-term success in global procurement strategies.

Key Considerations for Choosing the Right AC Contactor: Industry Insights

Choosing the right AC contactor is critical to ensuring the efficiency and reliability of your HVAC systems. Industry insights suggest that the global HVAC market is expected to reach $167 billion by 2025, with demand for robust and dependable components like AC contactors increasing. The selection process should consider factors such as voltage rating, duty cycle, and operational environment. For instance, the use of contactors rated for higher voltage applications can prevent potential failures, which is especially important in industrial settings.

**Tips:** Always check for certified ratings and standards such as UL or CE compliance, as these indicate that the contactor meets rigorous safety and performance criteria. Additionally, analyze your application’s specific load requirements; utilizing a contactor that matches or exceeds the load capacity can lead to improved longevity and reduced failure rates.

Another key consideration is the environmental conditions where the contactor will be employed. Reports indicate that over 30% of HVAC failures are attributed to improper component selection. Factors such as humidity, temperature fluctuations, and exposure to contaminants should inform your choice. Opting for contactors with appropriate IP ratings can safeguard against these environmental stresses.

**Tips:** Consult with manufacturers regarding their testing protocols and ensure that the contactor has been subjected to real-world conditions similar to your application. Understanding these elements will help in securing a reliable installation and maximizing system performance.

Innovations in AC Contactor Technology: Industry-Centric Enhancements

In the ever-evolving world of AC contactor technology, recent innovations play a crucial role in enhancing efficiency and reliability in industrial applications. New designs focus on reducing energy consumption while improving the lifespan of contactors. For instance, the integration of smart sensors allows for real-time monitoring of electrical loads, enabling predictive maintenance and minimizing downtime. This shift towards intelligent systems not only boosts performance but also aligns with sustainability goals in the global procurement landscape.

When selecting the ideal AC contactor, consider the following tips: firstly, assess the specific requirements of your application—such as voltage, current rating, and environmental factors—before making a choice. Secondly, prioritize manufacturers who offer robust support and detailed specifications; this ensures compatibility and performance longevity. Lastly, keep an eye on new technologies and enhancements, as advancements in materials and designs could substantially impact your operational efficiency and cost-effectiveness. By staying informed, procurement professionals can make strategic decisions that lead to long-term success.

Real-World Implementation: Success Stories of AC Contactors Across Sectors

In various sectors, the implementation of high-quality AC contactors has led to remarkable improvements in efficiency and reliability. For instance, in the manufacturing industry, companies have reported reduced downtime by 30% after upgrading their AC contactors, which are crucial for managing electrical power in heavy machinery. The successful integration of innovative contactor technology not only enhances productivity but also significantly lowers operational costs.

When selecting an AC contactor, it’s essential to assess the specific needs of your application. Consider factors such as voltage ratings, current carrying capacity, and environmental conditions. Tip: Always refer to the manufacturer's specifications to ensure compatibility with existing systems. This foresight can prevent costly errors and delays in projects.

Additionally, industry leaders in the renewable energy sector highlight the importance of choosing contactors that can handle the unique demands of solar and wind energy systems. A case study from a leading solar farm illustrates how the right AC contactor choice improved their energy conversion efficiency by 15%. Tip: Engage with suppliers to understand the latest developments in AC contactor technology to make informed decisions that drive success.

Challenges and Solutions in AC Contactor Selection for Global Industries

Selecting the right AC contactor can be a formidable challenge for global industries. The landscape of procurement is constantly evolving, driven by technological advancements and shifting market demands. According to the latest report from Research and Markets, the global AC contactor market is expected to grow at a CAGR of 5.8% from 2023 to 2030, highlighting the increasing need for reliable and efficient electrical components. However, businesses face challenges in ensuring compatibility, quality standards, and supply chain disruptions, which can hinder their operational efficiency.

One effective strategy to mitigate these challenges is conducting thorough supplier evaluations. Companies should assess suppliers based on their certifications, product range, and track record in delivering high-quality AC contactors. Furthermore, leveraging data analytics is crucial for forecasting demand and identifying potential risks in the supply chain. A recent survey by Frost & Sullivan indicates that organizations implementing predictive analytics saw a 30% reduction in procurement-related issues.

Tips: Always consider local regulatory requirements when selecting contactors for global projects. Ensuring compliance with international standards can save time and resources in the long run. Also, invest in supplier partnerships that offer technical support and after-sales service, which can be invaluable in navigating unforeseen challenges.

Your Ultimate Guide to Selecting the Best AC Contactor for Global Procurement Success - Challenges and Solutions in AC Contactor Selection for Global Industries

| Selection Criteria | Importance Level | Common Challenges | Potential Solutions |

|---|---|---|---|

| Voltage Rating | High | Incompatibility with existing systems | Conduct thorough system assessments |

| Current Rating | High | Overloading issues | Choose a contactor with higher rating |

| Temperature Range | Medium | Extreme conditions affecting performance | Select contactors rated for specific environments |

| Size and Form Factor | Medium | Space constraints | Consider compact designs |

| Control Voltage | Medium | Mismatch with control circuit | Verify control circuit specifications |

| Mounting Options | Low | Installation difficulties | Flexible mounting configurations |